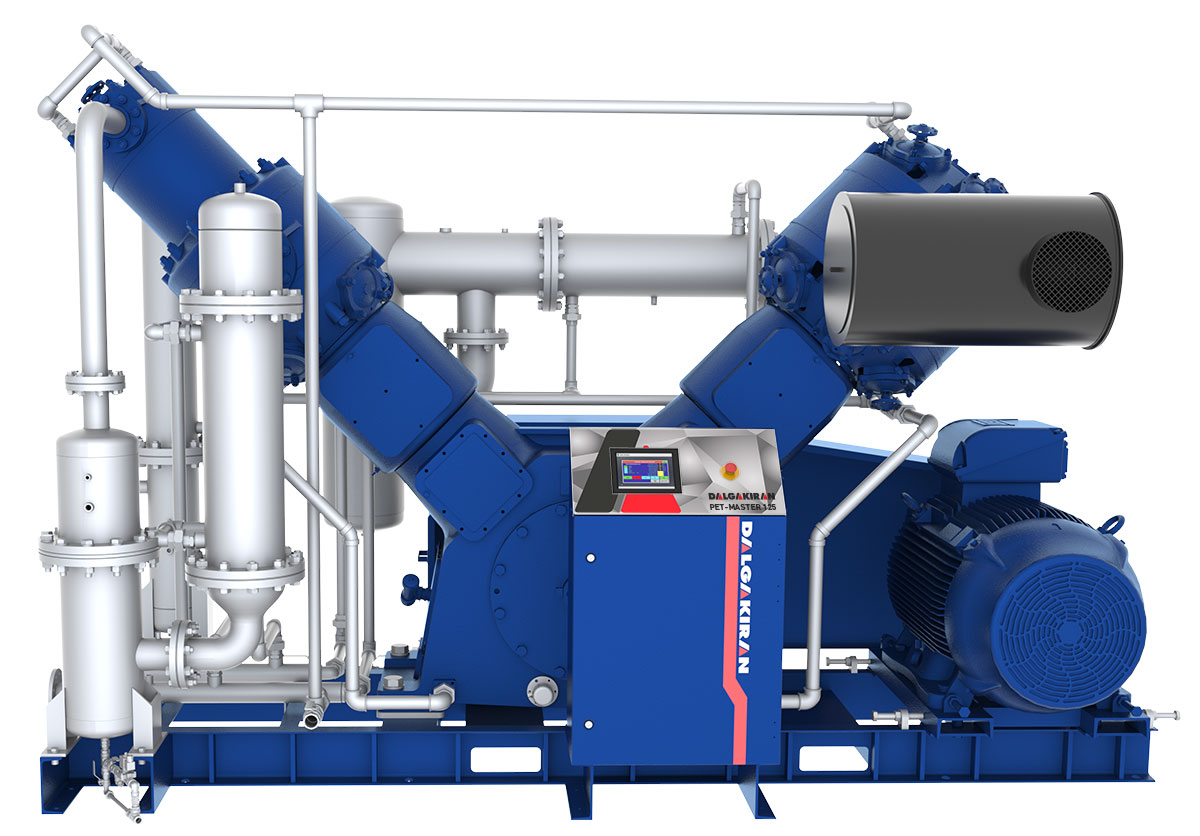

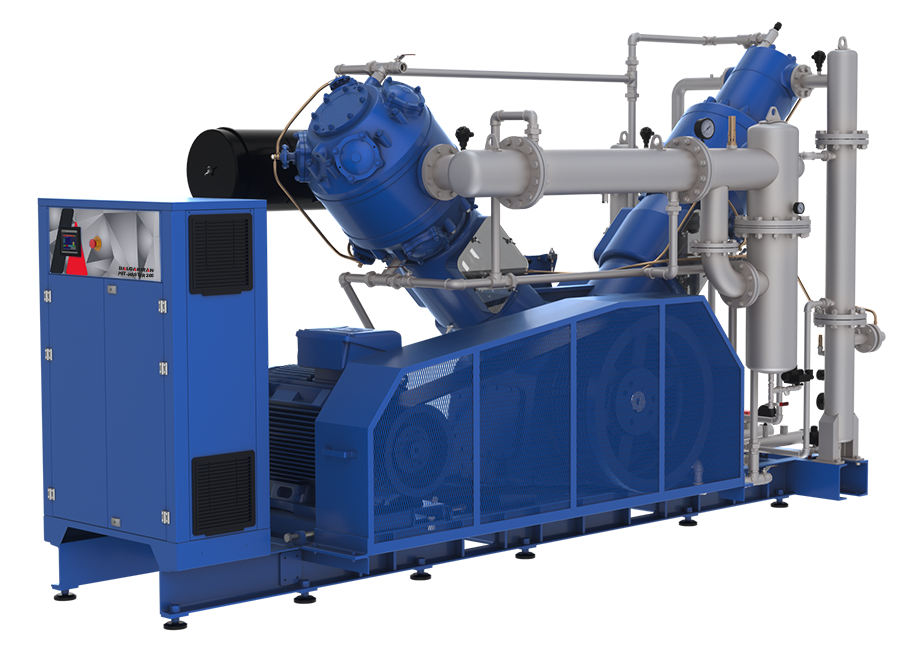

PET MASTER SERIES

We provide reliable and high-performance air solutions for the PET bottling, food and beverage industries requiring high compression.

| Model | Pressure | Capacity | Motor | Connection | Dimensions (mm) | Weight kg |

||||

| bar | psi | m³/min | cfm | kW/HP | Width | Length | Height | |||

| PET MASTER 50 | 40 | 580 | 3.6 | 127 | 37/50 | G 1 1/4" | 3647 | 1669 | 2395 | 5500 |

| PET MASTER 75 | 40 | 580 | 5.5 | 194 | 55/75 | G 1 1/4" | 3647 | 1669 | 2395 | 5500 |

| PET MASTER 100 | 40 | 580 | 7.4 | 261 | 75/100 | G 1 1/4" | 3673 | 1744 | 2470 | 6500 |

| PET MASTER 125 | 40 | 580 | 9.1 | 321 | 90/120 | G 1 1/4" | 3673 | 1744 | 2470 | 6500 |

| PET MASTER 150 | 40 | 580 | 11.6 | 410 | 110/150 | G 2" | 4192 | 1977 | 2814 | 7500 |

| PET MASTER 180 | 40 | 580 | 13.5 | 477 | 132/175 | G 2" | 4192 | 1977 | 2814 | 7500 |

| PET MASTER 220 | 40 | 580 | 16.4 | 579 | 160/215 | G 2" | 4192 | 1977 | 2814 | 7800 |

| PET MASTER 270 | 40 | 580 | 21.3 | 752 | 200/270 | G 2" | 4234 | 2203 | 2841 | 9200 |

| PET MASTER 300 | 40 | 580 | 23 | 812 | 220/300 | G 2" | 4234 | 2203 | 2841 | 9200 |

| Model | Pressure | Capacity | Motor kW/HP |

Connection | Dimensions (mm) | Weight kg |

||||||

| Minimum | Maximum | |||||||||||

| bar | psi | m³/min | cfm | m³/min | cfm | Width | Length | Height | ||||

| PET MASTER 75 VSD | 40 | 580 | 4.1 | 145 | 5.5 | 194 | 55/75 | G 1 1/4" | 3647 | 1670 | 2395 | 5600 |

| PET MASTER 125 VSD | 40 | 580 | 6.8 | 240 | 9.1 | 321 | 90/120 | G 1 1/4" | 3383 | 2411 | 2407 | 6650 |

| PET MASTER 180 VSD | 40 | 580 | 10.1 | 357 | 13.5 | 477 | 132/175 | G 2" | 4192 | 1977 | 2814 | 7750 |

| PET MASTER 220 VSD | 40 | 580 | 12.3 | 434 | 16.4 | 579 | 160/215 | G 2" | 4192 | 1977 | 2814 | 8000 |

| PET MASTER 300 VSD | 40 | 580 | 17.3 | 611 | 23 | 812 | 220/300 | G 2" | 4234 | 2203 | 2841 | 9500 |

• Compact structure, easy to install and assemble.

• Takes up less room than other products in its class, providing maximum oil-free air capacity in minimum space.

• Wear due to friction is minimized. This positively affects maintenance times and costs.

• Stainless water separator increases corrosion resistance.

• Soft start prolongs component life.

• IE3 efficiency-class electric motors

• Special loadless start system and automatic discharge system for loadless start

• Long life with low RPM thanks to 6 pole feature

• Water jacketed cast iron cylinders and bottom heads

• Specially designed high-speed stainless steel concentric valves

• High-strength cast iron oil sumps

• Dynamically balanced high-strength forged steel crankshaft and cast iron

• Special aluminium alloy pistons and forged steel connecting rods

• The intercoolers and aftercoolers use stainless steel pipes for more efficient heat transfer and better corrosion resistance.

• The coolers are designed to pass air through the body and water through the wall.

• The compact design of the pipe-type coolers ensures easy maintenance and very efficient cooling.

• Electrical components selected according to IEC, UL/cUL, CE standards, safety systems suitable for pressure class are used.

• Advanced, high-definition, user-friendly 6” colour touchscreen display (HMI)

• High speed, robustly built industrial type PLC infrastructure

• Encrypted Access Protection system with various levels of authorization

• Display of relevant data on the screen clearly, trend graph recording and active monitoring

• Alarm log records last 100 alarms

• Ethernet / ModBus communication as standard

• Flexible programmable / expandable Input / Output structure