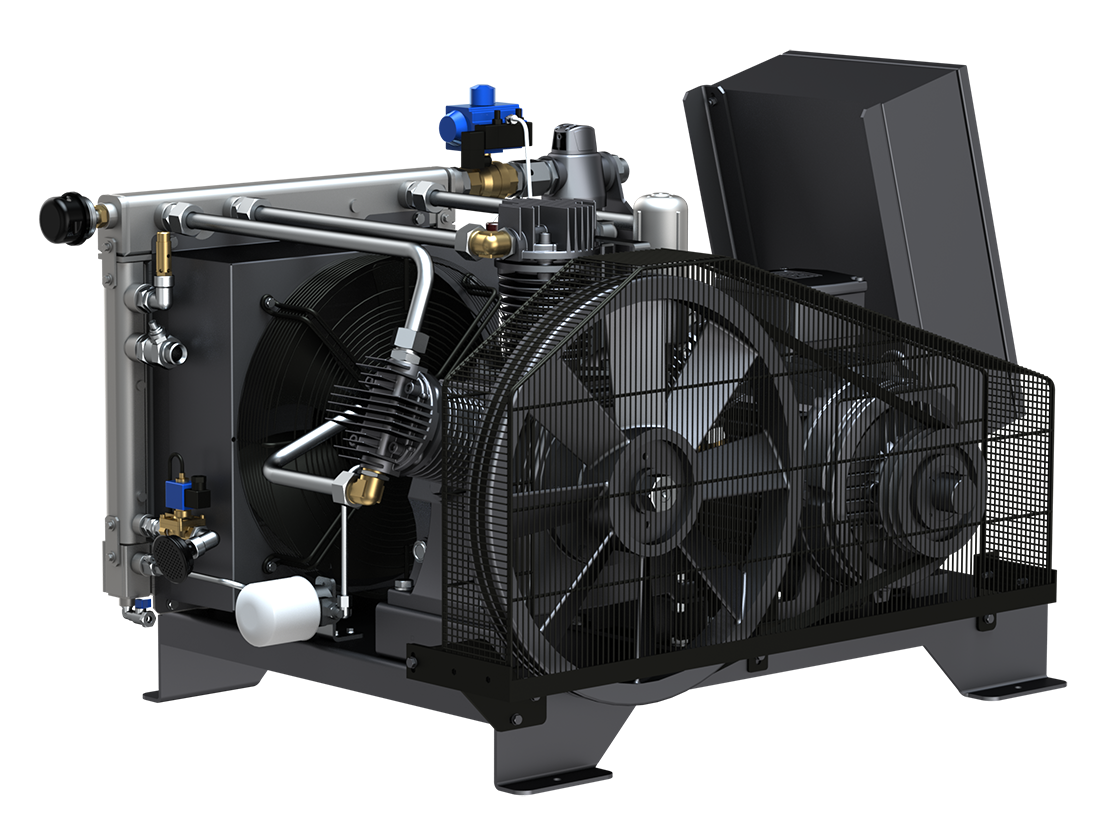

DBK GP SERIES

We provide reliable and high-performance air solutions for the PET bottling and food and beverage industries requiring high compression.

| Model | Pressure | Capacity (Intake) | Motor | Connection | Dimension (mm) | Weight | ||||||||||

| Min. bar - psi |

Max. bar - psi |

7 bar m³/min - cfm |

10 bar m³/min - cfm |

13 bar m³/min - cfm |

kW/HP | Width | Length | Height | kg | |||||||

| DBK 10 GP | 15 | 218 | 40 | 580 | 2.1 | 74 | 2.89 | 102 | 3.67 | 130 | 7,5/10 | 1” | 1430 | 1010 | 1025 | 350 |

| DBK 15 GP | 15 | 218 | 40 | 580 | 2.45 | 87 | 3.37 | 119 | 4.29 | 152 | 11/5 | 1” | 1430 | 1010 | 1025 | 400 |

| DBK 20 GP | 15 | 218 | 40 | 580 | 3.75 | 132 | 5.15 | 182 | 6.55 | 231 | 15/20 | 1” | 1430 | 1010 | 1025 | 410 |

| DBK 25 GP | 15 | 218 | 40 | 580 | 4.9 | 173 | 6.73 | 238 | 8.57 | 303 | 18,5/25 | 1 1/4” | 1500 | 1025 | 957 | 440 |

| DBK 30 GP | 15 | 218 | 40 | 580 | 5.56 | 196 | 7.65 | 270 | 9.74 | 344 | 22/30 | 1 1/4” | 1500 | 1025 | 957 | 480 |

| DBK 40 GP | 15 | 218 | 40 | 580 | 6.68 | 236 | 9.18 | 324 | 11.68 | 413 | 30/40 | 1 1/4” | 1500 | 1025 | 957 | 550 |

• Durable sliding bearings prolong maintenance periods and keep maintenance costs low.

• Next gen booster series offers high performance with the outstanding technology and design.

• Oil-trap air filtration system provides cleaner air.

• Energy-saving advanced cooling and lubrication systems.

• Integrated oil pump driven by the main motor lubricates the pistons, bearings and pins efficiently.

• Improved vibration level helps to keep maintenance costs down.

• Mains voltage and frequency monitoring, protection at certain limits

• Multiple compressor control for up to 8 compressors without the need for an external master controller

• Internal ModBus communication

• Alarm log records the last 9 alarms

• IE3 efficiency-class electric motors

• Belt pulley drive system

• Easy belt tensioning system

• Specially designed fan type cast pulley

• Star/delta motor starter

• Special loadless start system and automatic discharge system for loadless start

• Cast iron cylinder with cooling fins and special aluminium alloy top heads

• Specially designed long-life and high-speed stainless steel concentric valves

• High-strength cast iron sump

• Dynamically balanced cast steel crankshaft and counterweight

• Special aluminium alloy pistons and cast connecting rods

• 2-section aluminium radiator for air and oil cooling

• Bar-Plate outlet air cooling radiator

• Integrated oil and air cooler with inlet collector

• Electrical components selected according to IEC, UL/cUL, CE standards, safety systems suitable for pressure class are used.

• Inlet air control system

• High-pressure switch

• Manual condensate drainage valve

• Integrated check valve in air outlet line

• Belt pulley housing fence

• Outlet pressure manometer

• High pressure relief valve

• Oil pressure control

• Integrated particulate filter in inlet air line

• By-pass line for protection against high oil pressure